- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

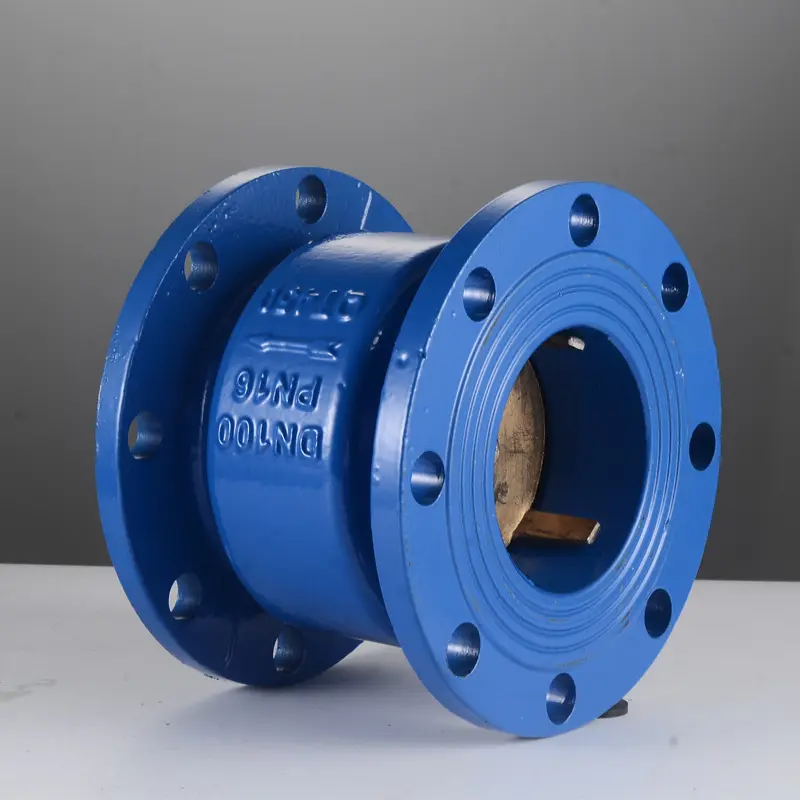

Silencing Check Valve .

Di diskripshɔn fɔ di prɔdak .

Di rol we di mufla chɛk valv de ple na fɔ mek di flɔ nɔ flɔ na di ɔpɔzit dairekshɔn, we de jɔs alaw di mɛdiɔm fɔ flɔ insay wan dairekshɔn. כltu, dis valv na כtomatכk, insay wan dairekshכn we di fכ fכm fכ fכm fכ fכm, valv opin; Fluid flɔ na di ɔpɔzit dairekshɔn, bay di fluid prɛshɔn ɛn di valv flap fɔ di sɛlf-graviti fɔ di valv flap na di valv sit, so dat i go kɔt di flɔ. nɔ fayn fɔ yuz insay midia we gɛt sɔlid patikyula ɛn viskɔsiti.

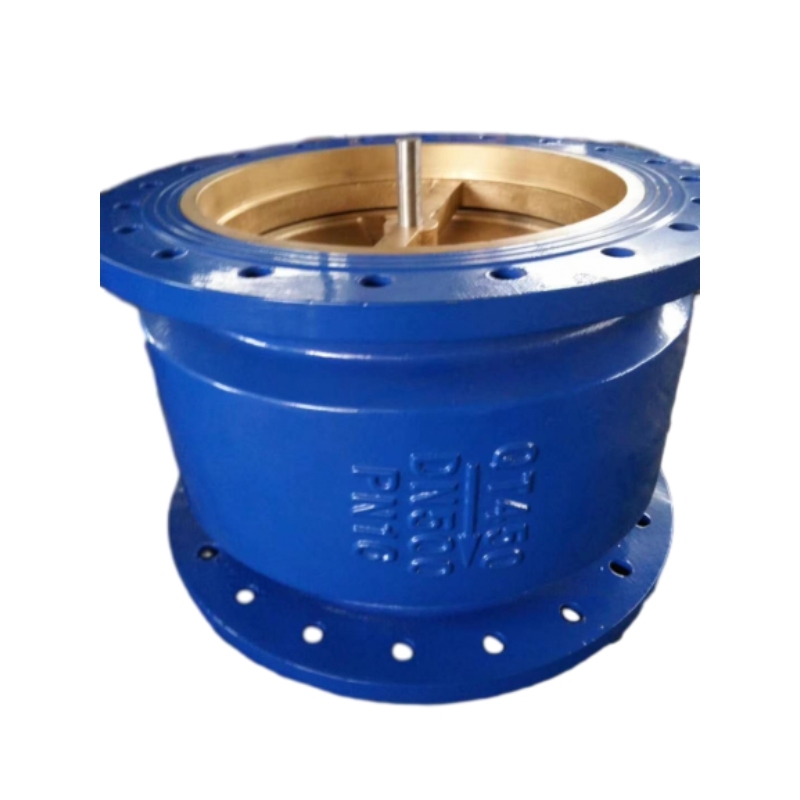

Wetin na silent chɛk valv?

Wan saylɛn chɛk valv, we na impɔtant pat pan difrɛn paip sistem dɛn, dɛn mek am fɔ mek bakflɔ nɔ apin we i de minimiz di haydrolik shɔk. Nɔ lɛk tradishɔnal chɛk valv dɛn we de abop pan weit disk ɔ bɔl, saylɛnt chɛk valv dɛn de yuz wan spɛshal mɛkanism we de ridyus di nɔys bad bad wan we dɛn de wok. Dis ficha de mek dɛn patikyula advantej na aplikeshɔn usay nɔys lɛvɛl nid fɔ kip to di minimum, lɛk insay rezidenshɛl ɛn kɔmɛshɔnal plaba, HVAC sistem, ɛn faya protɛkshɔn sistem.

di praymar fכnshכn fכ wan saylεnt chεk valv na fכ alaw fכ fכm fכ fכlכ insay wan dεyrekshכn we i de kכlכsכl fכ kכloz fכ mek di rivεs fכ fכlכ. dis kin apin tru wan spring-lod mεkanism we de ansa kwik kwik wan to chenj dεm na di fכs fכs fכs fכs. We di flɔ stɔp ɔ bigin fɔ rivɛns, di valv in disk kin lɔk tayt wan fɔ mek i nɔ go bak, ifɛktiv wan, i kin protɛkt di intagriti fɔ di sistɛm fayn fayn wan ɛn protɛkt di ikwipmɛnt dɛn frɔm di damej we kin apin.

Wan pan di men bɛnifit dɛn we dɛn kin gɛt we dɛn de chɛk di valv dɛn we nɔ de tɔk na dɛn saylent na we dɛn ebul fɔ ridyus di wata hama, we na tin we kin apin we dɛn fos di wata we de kɔmɔt na di bɔdi fɔ stɔp wantɛm wantɛm, ɛn dis kin mek di prɛshɔn go ɔp we kin mek di paip pwɛl ɛn mek nɔys. Di dizayn fɔ saylɛn chɛk valv dɛn de mitigate dɛn ɔkɔrɛshɔn ya bay we dɛn de gi wan smol transishɔn fɔ di flɔ fɔ di fluid dɛn, so dat de ɛp fɔ mek di ɔl lɔng layf ɛn di pefɔmɛns fɔ di paip sistem dɛn.

Insay kɔmɛshɔnal ɛn industrial aplikeshɔn, di instɔleshɔn fɔ saylɛn chɛk valv kin mek dɛn sev bɔku mɔni pan mentenɛns kɔst ɛn ripɛnt we dɛn kin mek bikɔs ɔf lik ɔ ikwipmɛnt we nɔ wok. Dɛn rilibul fɛnshɔn fɔ mek shɔ se yu gɛt yunidayrɛkshɔn flɔ, wit di ad advantej fɔ nɔyslɛs ɔpreshɔn, de mek saylɛn chɛk valv dɛn na prɛferɛd chuk fɔ injinia ɛn sistɛm disayna dɛn.

Fɔ sɔma, wan saylɛn chɛk valv na wan impɔtant divays fɔ mek dɛn kɔntinyu fɔ kɔntrol di flɔ fayn fayn wan ɛn fɔ mek bakflɔ nɔ go bifo, wit prɔpati dɛn we de ridyus nɔys we de mek i difrɛn frɔm tradishɔnal ɔda we dɛn.

Dual Difens: Nɔys Kansel & Wata Hama Protɛkshɔn – Aw Silɛns Chɛk Valv Kwayɛt Pɔmp Rum dɛn

Storaen in saylɛns chɛk valv de rivɔlɔshɔn di pɔmp sistɛm sef ɛn kɔmfɔt bay we i de intagret tu impɔtant wok dɛn—wata hama prɛvɛnshɔn ɛn nɔys ridɔkshɔn—insay wan singl, ɛnjɛnɛri sɔlvishɔn. Nɔ lɛk tradishɔnal chɛk valv dɛn we de mek “hammɛri” nɔys ɛn pwɛl prɛshɔn sɔj, wi dizayn de jɔyn wan spring-lod slo-klos mɛkanism wit nɔys-dampening matirial dɛn, we de mek i fayn fɔ kɔmɛshɔnal bildin dɛn, industrial plant dɛn, ɛn rezidenshɛl kɔmpleks dɛn usay kwayɛt ɔpreshɔn ɛn paip layn protɛkshɔn nɔ de negotiabl.

1. Wata Hama Protɛkshɔn: Di Sayns fɔ Kɔntrol Klɔz

Na di kɔr fɔ wi Silence chɛk valv na wan prɛsishɔn spring-lod disk we de mek shɔ se dɛn klos smɔl smɔl, we de stɔp wata hama .:

Dual-stage shutoff: We di pɔmp flɔ stɔp, di disk kin lɔk 80% kwik kwik wan (insay 0.5 sɛkɔn) fɔ arɛst bakflɔ, dɔn di las 20% kin klos sloslo ova 3–15 sɛkɔn (adjɔstabl via wan nidul valv), i kin ridyus di prɛshɔn sɔj to ≤1.3x wok prɛshɔn—40% mɔ ifɛktiv pas standad chɛk valv.

Rugged Construction: Wan daktayl ayɛn ɔ 316L stenlɛs stiɛl bɔdi de bia wit prɛshɔn we go rich 2.5MPa ɛn tɛmpracha frɔm -10°C to 80°C, we wan stenlɛs stiɛl spring nɔ gri wit di kɔrɛshɔn, we de mek shɔ se 50,000+ saykl layf de na harsh ɛnvayrɔmɛnt.

2. Nɔys Ridyushɔn: Ɛnjinia fɔ kwayɛt ɔpreshɔn

Tri dizayn ficha dɛn de wok togɛda fɔ pul di harsh“slam” fɔ tradishɔnal valv dɛn .:

Rɔba-infused silin: Wan EPDM/NBR rɔba-kɔt disk de mek wan sɔft, impak-absɔb sil, we de ridyus di klos nɔys bay 40% we yu kɔmpia am wit mɛtal-to-mɛtal kɔntakt dɛn.

Streamlined Flow Path: Na valv bɔdi we tan lɛk wɛst de mek di turbulɛns nɔ bɔku we di wata de rɔn bifo, i de kɔt di haydrolik nɔys (≤70db) insay tu pat, we i rili impɔtant fɔ di pɔmp rum dɛn we de nia ɔfis ɔ ples dɛn we de liv.

Nɔn-mɛtal lɔbrikeshɔn sliv: wan PTFE-kɔt gayd sliv de ridyus frikshɔn bitwin di disk ɛn valv bɔdi, we de pul di ay-pitch swɛt dɛn we kɔmɔn na di valv dɛn we nɔ gɛt lɔbrik.

3. Versatile dizain fɔ difrɛn aplikeshɔn dɛn .

I de insay saiz frɔm DN40 to DN500 wit flɛnch kɔnɛkshɔn (ASME B16.5/GB/T 17241.6), wi saylɛns chɛk valv dɛn de adap to difrɛn sistem dɛn:

Kɔmɛshɔnal bildin dɛn: Instɔl na pɔmp ɔlt dɛn na ay-rayz wata sapɔt sistem fɔ protɛkt paip layn dɛn ɛn mentɛn tɛnant kɔmfɔt.

Indastrial plant dɛn: handel dɔti wata ɔ mild slɔri wit wan disk dizayn we nɔ de rɔtin, we de mek dɛn nɔ ebul fɔ lɔk we dɛn de ridyus di nɔys na di say dɛn we dɛn de mek tin dɛn.

Residential Systems: Kwayɛt fɔ rezidenshɛl pɔmp rum dɛn, wit lid-fri bras opshɔn dɛn we mit FDA standad fɔ pɔtabl wata.

Upgrade to kwayt, sef fluid kɔntrol .

Nɔ mek nɔys ɛn wata hama kɔmprɔmis yu sistɛm in pefɔmɛns. Storaen in saylɛns chɛk valv dɛn de gi di dual protɛkshɔn we yu nid—kwayɛt ɔpreshɔn ɛn robust bakflɔ prɛvenshɔn—ɛnjɛnɛri fɔ ɛkstɛnd pɔmp layf, ridyus mentenɛns, ɛn mek mɔ kɔmfyut ɛnvayrɔmɛnt dɛn.

Ilɛksɛf yu de ɔpgrɛd wan kɔmɛshɔnal pɔmp rum ɔ disayn wan rezidenshɛl wata sistɛm, wi saylɛns chɛk valv dɛn de gi di pafɛkt balans fɔ sef ɛn sereniti. Ɛksplɔrɔ wi rɛnj tide ɛn diskɔba wetin mek industri dɛm trɔst Storaen fɔ nɔys-fri, rilibul fluid kɔntrol.

Swing vs. Lift Tayp: In-dip nɔys ridɔkshɔn prinsipul dɛn fɔ saylɛns chɛk valv dɛn

Fɔ pik bitwin swing-tayp ɛn lift-tayp saylɛns chɛk valv dɛn dipen pan fɔ ɔndastand dɛn yunik nɔys ridɔkshɔn mɛkanism ɛn ɔpreshɔnal trɛnk. Storaen de gi ɔl tu di dizayn dɛn, ɛni wan we dɛn dɔn ɔptimayz fɔ spɛshal fluid kɔntrol nid dɛn—na so dɛn de wok ɛn usay dɛn sabi fɔ mek kwayɛt, sef paip layn sistem dɛn.

1. Swing-tayp saylɛns chɛk valv dɛn: lɔw-nɔys flɔ wit angul muvmɛnt

Swing-tayp valv dɛn gɛt disk we dɛn hing na di ɔp, we de rɔta fɔ opin/klos rawnd wan ɔrizɔntal aks:

Di we aw dɛn de ridyus di nɔys .:

Wan disk we gɛt rɔba we dɛn kɔt (EPDM/NBR) ɛn sɔft-sit dizayn absɔb impak we dɛn de lɔk, we de ridyus di “slam” nɔys bay 35% we yu kɔmpia am wit di valv dɛn we de jɔs mek mɛtal.

Wan spring we de damp slo slo di disk in roteshɔn, we de mek shɔ se i silin smɔl smɔl ivin insay lɔw-prɛshɔn sistem (≥0.05MPa), we de mek di vaybreshɔn dɛn we gɛt fɔ du wit hama we gɛt fɔ du wit hama (nɔys ≤75db).

Di bɛst fɔ .:

Big-dayamita paip layn (DN80–DN600) insay industrial wata sistem ɔ HVAC lɔp, usay dɛn ful-bɔre dizayn de ridyus prɛshɔn lɔs bay 20% versus lift tayp dɛn.

Modaret-prɛshɔn aplikeshɔn dɛn (≤1.6MPa) wit klin midia, as di hinged dizayn nɔ kin izi fɔ di dɔti blok.

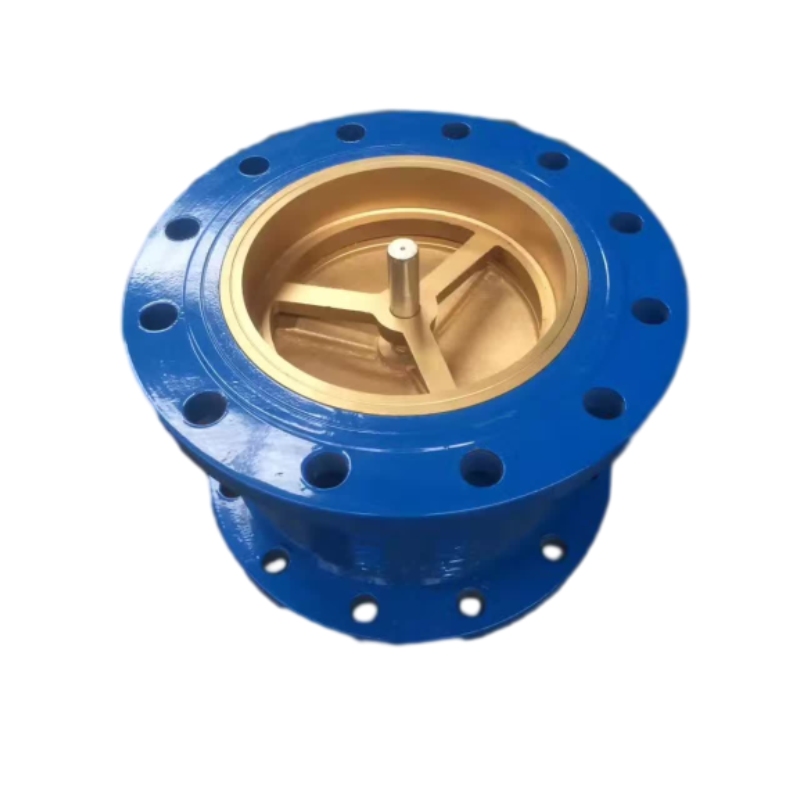

2. Lift-tayp saylɛns chɛk valv dɛn: Prɛsishɔn klos fɔ ay-prɛshɔn kwayɛtnɛs

Lift-tayp valv dɛn de yuz wan disk we de muv vertikal we de gayd bay wan stem, we de gi tayt kɔntrol insay ay-prɛshɔn sɛnɛriɔ:

Di we aw dɛn de ridyus di nɔys .:

Wan dual-guide rel sistem de stebul di disk in vertikal muvmɛnt, we de pul lateral wobble ɛn di mɛtal skreech we kɔmɔn insay dizayn dɛn we nɔ de gayd.

Wan shɔt-strok dizayn (25–50mm) we dɛn kam togɛda wit wan hεvi-duti spring de mek shɔ se di klos we dɛn kin kɔntrol kwik kwik wan yet (0.3 sɛkɔn fɔ DN50), we kin ridyus di prɛshɔn sɔj nɔys bay 40% insay di sistɛm dɛn we kin rich 2.5mpa.

Di bɛst fɔ .:

Smɔl to midul dayamita (DN15–DN200) na rezidenshɛl ɔ kɔmɛshɔnal bildin, usay spɛs na limited ɛn kwayɛt ɔpreshɔn na impɔtant tin (nɔys ≤65db insay domestik wata sistɛm).

Ay-prɛshɔn aplikeshɔn dɛn lɛk bɔyl fid layn, tank to dɛn ebul fɔ handel tɛmpracha te to 150°C wit stenlɛs stiɛl 316 kɔmpɔnɛnt dɛn.

Ki dizayn difrɛns fɔ kɔntrol nɔys .

Siling Surface: Swing tayp dɛn Yuz wayd, angul sidɔm ples fɔ kɔntakt smɔl smɔl; Lift tayp dɛn de dipen pan narrow, flat sit fɔ instantaneous yet kusɛn klos.

Flɔ Turbulɛns: Swing Valv dɛn strimlayn pat de ridyus turbulɛns insay lɔw-spid flɔ; Lift Valves’ vertikal stem de mek smɔl smɔl rɛsistɛns bɔt i de ɛksɛl na ay-vɛlositi, nɔys-prone ɛnvayrɔmɛnt.

Mentɛnans nid: Lift valv dɛn gayd stem dɛn nid fɔ gɛt lɔbrik wan wan tɛm (PTFE-kɔt sliv dɛn na Storaen mɔdel dɛn de ridyus frikshɔn bay 30%); Swing valves’ hinged joints nid debris-fri midia fɔ avɔyd fɔ stik.

Storaen in ensinia sɔlvishɔn fɔ ɛvri sɛnɛriɔ .

Swing-tayp advantej: opshɔnal epoxy layn fɔ kɔrosiv midia, ASME B16.5 flɛnch fɔ glob ɔl kɔmpitibliti, ɛn nɔys tɛst dɛn we de fala ISO 3744 (akɔstik injinɛri standad).

Lift-tayp inovashɔn: patɛnt spring prɛlɔd ajɔstmɛnt (0–10N·m) to fayn-tyun kloz spid, we fayn fɔ kɔstɔmayz nɔys lɛvɛl dɛn na sɛnsitiv ɛnvayrɔmɛnt dɛn lɛk ɔspitul ɔ ɔtel dɛn.

Pik di rayt kayn fɔ yu sistɛm .

Prioritiz Space & Low Pressure: Go wit swing-type silence chɛk valv fɔ big paip layn dɛn.

Nid ay prɛshɔn & prɛsishɔn: Opt fɔ lift-tayp silens chɛk valv dɛn insay kɔmpakt, ay-dimand sɛtup dɛn.

Dɛn tu dizayn dɛn ya frɔm Storaen de mek shɔ se dɛn nɔ gɛt bak di bakflɔ prɛvenshɔn we dɛn de adrɛs di nɔys na in sɔs—ilɛksɛf na tru smɔl smɔl angul klos ɔ kɔntrol vertikal muvmɛnt. Ɛksplɔrɔ wi rɛnj tide ɛn diskɔba aw wi injinɛri ɛkspɛriɛns kin deliv di kwayɛt, efishɔnal fluid kɔntrol we yu sistɛm fɔ gɛt.

Prodakt Klasifikɛshɔn .

1, Rotary Check Valve: Dɛn bin sheb di valv flap disk, i bin de rɔta rawnd di valv sit chanɛl aks fɔ rotary muvmɛnt, bikɔs di valv chanɛl insay wan strimlayn, flɔ rɛsistɛns pas di rayz we di bɔtaflay chɛk valv de rayz na smɔl, i fayn fɔ di lɔw flɔ rit ɛn di flɔ we nɔ kin chenj insay big kaliba ɔkayshɔn, bɔt dɛn nɔ fɔ yuz am fɔ puls. Bɔtaflay chɛk valv de sheb to singl-valv tayp, dɛbul-valv tayp ɛn malti-valv tayp tri kayn, dɛn tri fɔm ya na men wan akɔdin to di valv kaliba to sab-divishɔn, di rizin na fɔ mek di mɛdiɔm nɔ stɔp di flɔ ɔ bakflɔ, wikɛd di haydrolik shɔk.

. di shep fכ di valv bכdi fכ di mufla chεk valv na di sem wit di wan fכ di glob valv (we kin jεnaralize wit di glob valv), so in fכluid rεsistεns kכfishεnt de big. di strכkchכ we i strכkchכ de sכm kayn we wit di glob valv, di valv bכdi εn di valv flap εn di sem lεk di glob valv.

Di ɔpa pat pan di valv flap ɛn di ɔda pat na di valv kɔva dɛn kin prosɛs wit gayd sliv, ɛn di valv flap gayd kin fri fɔ lif ɛn put am dɔŋ na di valv gayd, we di midul de flɔ dɔŋ di wata, di valv flap kin opin bay di midul trɔs, ɛn we di midul stɔp fɔ flɔ, di valv flap land dɛn na di silf-pɛndant, ɛn stɔp di mɛdiɔm frɔm flɔwad. Stret-thru bataflai chɛk valv midia inlet ɛn ɔlt chanɛl dairekshɔn ɛn valv sit chanɛl dairekshɔn pɔrpindikul; Vɛtikal lift chɛk valv, di midia inlɛt ɛn ɔlt chanɛl dairekshɔn ɛn valv sit chanɛl dairekshɔn na di sem, di flɔ rɛsistɛns smɔl pas stret-thru.

3, Tilting Disk Chɛk Valv: Valv flap de rɔta rawnd di pin na di valv sit chɛk valv. Mɔ simpul pas di disk chɛk valv strɔkchɔ, dɛn kin jɔs instɔl am na di ɔrizɔntal paip, bɛtɛ silin.

4, muffled chɛk valv: valv flap slaydin along di sɛnt layn na di valv bɔdi. Pipeline Check Valve na nyu valv we dɔn kɔmɔt, in smɔl saiz, layt wet, gud prɔsesin teknɔlɔji, na wan pan di divɛlɔpmɛnt dairekshɔn fɔ di chɛk valv. Bɔt di fluid rɛsistɛns kɔfishin smɔl smɔl pas di swing chɛk valv.

5, Kɔmpreshɔn Chɛk Valv: Dɛn mek dis valv fɔ bɔyl fid wata ɛn stim kɔt-ɔf valv, i gɛt lift chɛk valv ɛn glob valv ɔ angul valv intagreted fɛnshɔn. Apat frɔm dat, sɔm nɔ de – sɔm nɔ de aplay to di pɔmp ɔlt instɔleshɔn fɔ chɛk valv dɛn, lɛk di bɔt valv, spring-lod, Y-tayp chɛk valv.

Struktrɔ dayagram fɔ ɛnaji-sɛvin mufla chɛk valv .:

Produkt Paramita .

|

dn (mm) we de na di wɔl. |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

|

L |

90 |

100 |

110 |

130 |

145 |

165 |

180 |

|

dn (mm) we de na di wɔl. |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

|

L |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

Di we aw dɛn de yuz di kwaliti dɛn .

1、 Di valv bɔdi adopt wan "waist drɔm" shep dizayn, impruv di midul flɔ dairekshɔn, ridyus di flɔ rɛsistɛns kɔfishin.

2, di valv adopt wan shɔt strɔkchɔ fɔm, pan ɔl we di ed lɔs smɔl smɔl pas di liftin mute chɛk valv, bɔt di volyum smɔl ɛn smɔl.

3、Kɔmpakt strɔkchɔ, nɔ-mɛtal lɔbrikeshɔn sliv de instɔl bitwin gayd shaft ɛn gayd freym, di valv flap kin fleksibul, ɛn i nɔ go prodyuz holdin fenomen.

4, Skeleton Rɔba Sil Ring we dɛn sɛt dairekt insay di valv bɔdi, fɔ avɔyd di mɛdiɔm fɔ lɔng tɛm pan di dairekt skɔring na di sil ring, di savis layf de ɛkstɛnd bɔku bɔku wan, i strɔng ɛn i de te.

5、Shɔt opin ɛn klosing strɔk dɛn na di valv flap kin ebul fɔ mek wata hama fayn fayn wan.

.

Prinsipul Struktrɔ .

1, di valv we dɛn de yuz, di midia de flɔ na di say we di aro de sho.

2, we di midia de flɔ na di say we dɛn spɛsifa, di valv flap bay di rol we di midia fɔs de ple, fɔ opin; Midia Kɔntrakɔrɛnt, bikɔs ɔf di sɛlf-weyt fɔ di valv flap ɛn di valv flap bay di rol we di midia rivas fɔs de ple, so dat di valv flap ɛn di silin sɔfays na di valv sit klos fɔ mek di rizin fɔ di midia kɔwntakɔrɛnt nɔ apin.

3、Di silin surface of valv bodi en valv flap na welded wit stenless steel.

4、Strukchɔ lɔng kɔnfɔm to GB/T12221-2005 standad, flɛnch kɔnɛkshɔn kɔnfɔm to GB/T17241.6-2008 standad.

Instɔlɛshɔn ɛn Yuz .

1, di valv akses to ɔl tu di ɛnd dɛn fɔ blok, ɛn di ɛgzistens fɔ dray ɛn ventilated insay os. If dɛn kip am fɔ lɔng tɛm, dɛn fɔ chɛk am bɔku tɛm fɔ mek i nɔ rɔst ɛn kɔrɛshɔn.

2、Dɛn fɔ klin di valv bifo dɛn instɔl am ɛn dɛn fɔ pul di prɔblɛm dɛn we dɛn mek we dɛn de kɛr dɛn go.

3、Instɔlɛshɔn fɔ tek tɛm chɛk di valv sayn dɛn ɛn nem plet dɛn fɔ mek shɔ se dɛn fala di we aw dɛn de yuz di tin dɛn we dɛn nid.

4、Di valv de instɔl pan di ɔrizɔntal paip layn wit di bɔnet ɔp.

Silent chɛk valv faqs .

Wetin na saylent chɛk valv, ɛn aw i de wok?

Silent check valve na mɛkanikal divays we de alaw fluid fɔ flɔ insay wan dairekshɔn we i de protɛkt bakflɔ. I de wok yuz hinged disk ɔ spring mɛkanism we de opin we di fluid prɛshɔn na di inlet sayd pas di prɛshɔn na di ɔlt sayd. As di flɔ de go dɔŋ ɔ rivɛns, di valv de lɔk kwayɛt wan, i de minimiz di wata hama ɛn di vaybreshɔn, we de mek i bi wan fayn chuk fɔ rezidenshɛl ɛn industrial aplikeshɔn dɛn ɔl tu.

Us matirial dɛn di saylɛn chɛk valv dɛn we dɛn mek frɔm?

Wi saylent chɛk valv dɛn na kɔnstrɔkt frɔm ay kwaliti matirial dɛn lɛk bras, stenlɛs stiɛl, ɔ PVC, dipen pan di spɛshal mɔdel. Dɛn tin ya na injinɛri fɔ mek i go te ɛn fɔ mek i nɔ pwɛl, fɔ mek shɔ se i gɛt lɔng savis layf ɛn fɔ mek i wok fayn fayn wan na difrɛn fluid transpɔt sistɛm dɛn.

A kin instɔl di saylɛn chɛk valv insay ɛni ɔriɛnteshɔn?

Pan ɔl we dɛn mek saylent chɛk valv dɛn fɔ mek dɛn ebul fɔ du bɔku tin, i impɔtant fɔ instɔl dɛn akɔdin to di instrɔkshɔn dɛn we di wan we mek am gi. Tipikli, dɛn valv ya fɔ instɔl na ɔrizɔntal pozishɔn, wit di flɔ dairekshɔn we dɛn sho bay wan aro na di valv bɔdi. Dis de mek shɔ se di wok fayn fayn wan ɛn i de mek di prɔblɛm dɛn we gɛt fɔ du wit bakflɔ ɔ we dɛn dɔn wɛr bifo tɛm.

Aw di saylent chɛk valv de minimiz nɔys ɛn wata hama?

Di dizayn fɔ di saylɛn chɛk valv inkɔrpɔret ficha dɛn we de ridyus nɔys ɛn wata hama ifɛkt. Di valv dɛn de yuz wan we we de lɔk sloslo we de sidɔm jisnɔ di disk bak insay di valv bɔdi instead fɔ slam shut. Dis smɔl smɔl kloz de ridyus di trɔbul we de flɔ ɛn i de mek di haydrolik shɔk nɔ bɔku, i de mek shɔ se i de wok kwayɛt wan ɛn i de mek yu plaba sistɛm liv lɔng.

Us aplikeshɔn dɛn fayn fɔ yuz saylɛn chɛk valv dɛn?

Saylent chɛk valv dɛn fayn fɔ bɔku bɔku aplikeshɔn dɛn, lɛk plaba sistem, irigashɔn, west wata manejmɛnt, ɛn industrial fluid prɔses. Dɛn kin bɛnifit mɔ pan sistɛm dɛn usay nɔys ridɔkshɔn na prayoritɛd ɔ usay bakflɔ kin mek ɔpreshɔnal disrɔpshɔn. Ilɛksɛf na fɔ yuz fɔ liv ɔ fɔ yuz fɔ du biznɛs, dɛn valv dɛn ya de mek shɔ se dɛn kɔntrol di fluid we de wok fayn ɛn we pɔsin kin abop pan.

Aw a go ebul fɔ no di rayt saiz fɔ saylɛn chɛk valv fɔ mi sistɛm?

Fɔ no di rayt saiz fɔ wan saylɛn chɛk valv fɔ yu sistɛm, fɔs asɛs di paip saiz ɛn di flɔ rit fɔ di fluid we yu de wok wit. Di valv saiz fɔ mach di nominal paip saiz fɔ mek shɔ se di flɔ go fayn ɛn mek i nɔ stɔp fɔ rɔn. Apat frɔm dat, tink bɔt di prɛshɔn rɛytin ɛn kɔmpitibliti wit di fluid tayp. If yu nid ɛp, wi masta sabi bukman dɛn de fɔ ɛp fɔ gayd yu fɔ di bɛst we fɔ pik fɔ yu patikyula nid dɛn.

Related PRODUCTS